Bearing component measuring instruments can be widely used in precision machinery manufacturing companies such as automotive parts, bearings, machine tools, and scientific research and quality inspection institutions.

It is suitable for bearing factories, precision shaft manufacturers and machine tool factories to select assembled bearings for use. It can also be used as a reliable tool for research and analysis in professional laboratories. It is an equipment guarantee for universal assembled bearing manufacturers.

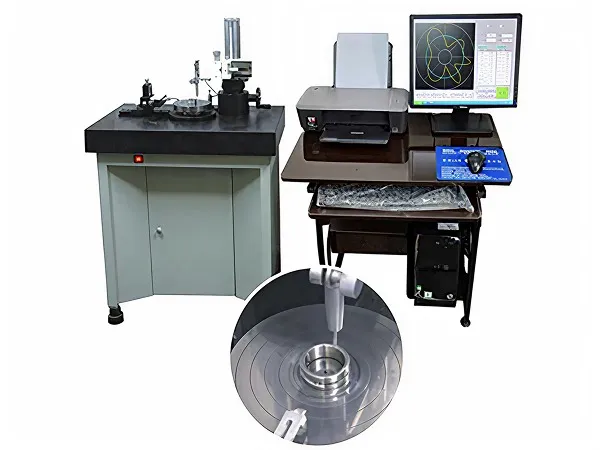

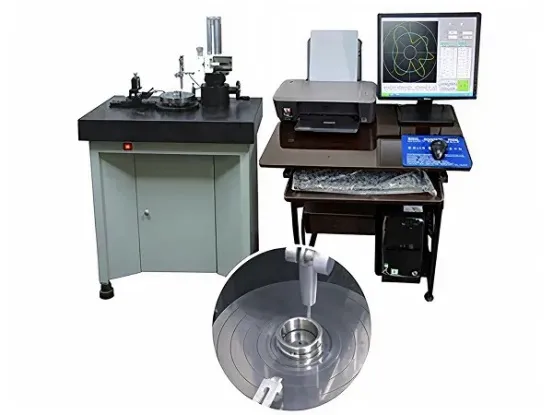

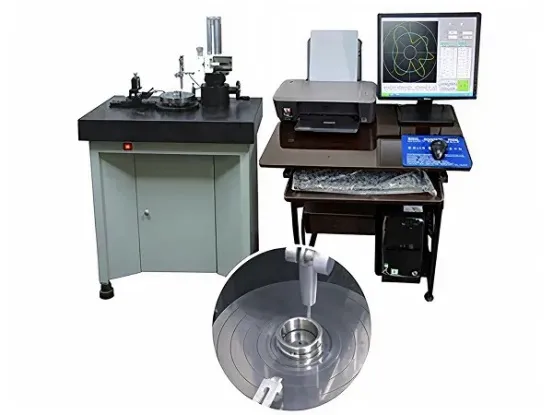

The instrument uses a servo motor to control shaft speed and a torque sensor to measure the friction torque of the shaft. A computer controls the entire measurement process, displaying and storing the measurement results and torque curves. The instrument is suitable for bearing manufacturers, universities, research institutes, and other enterprises and institutions.

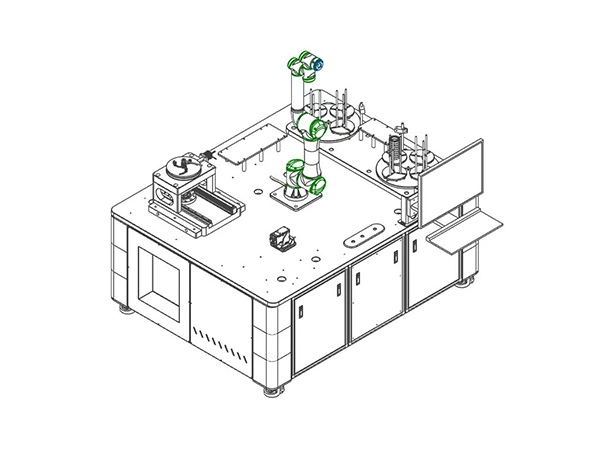

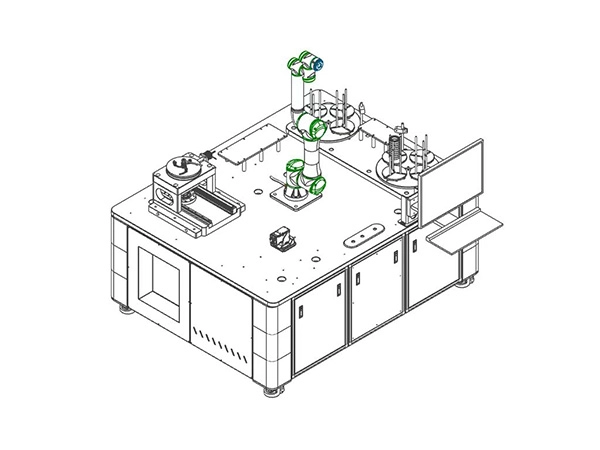

The company has strong capabilities in the design and manufacture of various high-precision mechanical parts such as gas hydrostatic bearings and dense bead slewing bearings. It can undertake non-standard design, manufacturing, assembly and commissioning of various precision mechanical parts that meet users' requirements for different motion forms such as rolling and sliding, and different functions such as bearing and guiding, and provide customers with customized solutions.

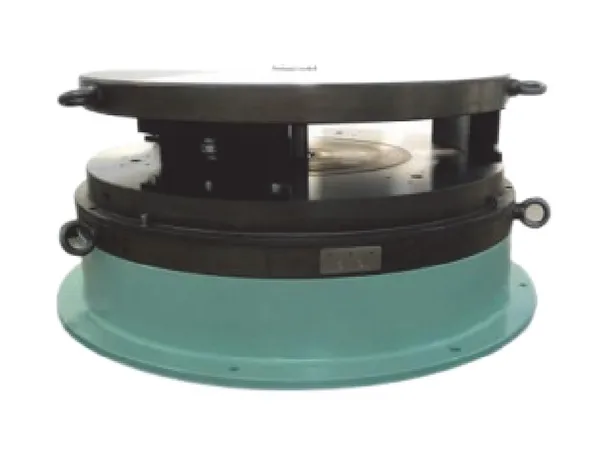

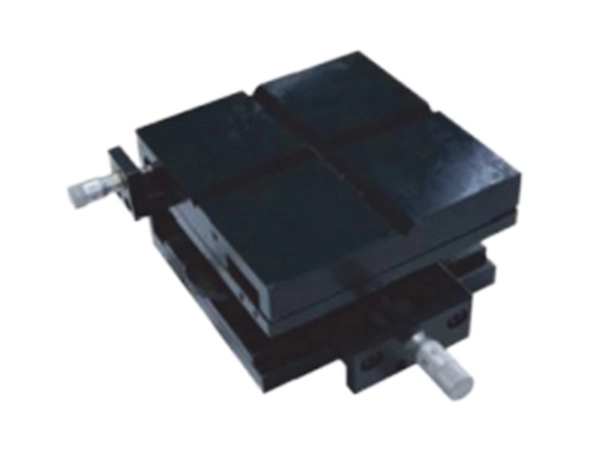

The two-dimensional worktable can realize translational motion in the X and Y directions during measurement. The rotary worktable can realize V-shaped positioning and pitch angle adjustment during measurement.

Bearing measuring instruments are specialized devices used to assess the geometric and functional characteristics of bearings, such as diameter, roundness, surface finish, and runout.These instruments employ technologies like laser scanning, contact probes, or optical sensors to achieve micron-level accuracy, ensuring bearings meet stringent industrial standards like ISO 1940.

At ZYS, our instruments integrate advanced algorithms to detect minute deviations that could lead to bearing failure.They are essential for quality control in manufacturing, helping to prevent costly downtime and enhance product reliability.

Common types include gauges for static measurements and testers for dynamic analysis under load. By providing precise data, these tools enable engineers to optimize bearing design, installation, and maintenance. With applications ranging from automotive engines to wind turbines, ZYS instruments deliver consistent results even in harsh environments.

Precision component design and processing technology as a benchmark

Precision measurement structure design technology

Various types of sensors and precision measurement circuit design and application technology

Data acquisition, analysis and processing, real-time judgment, and error separation technology

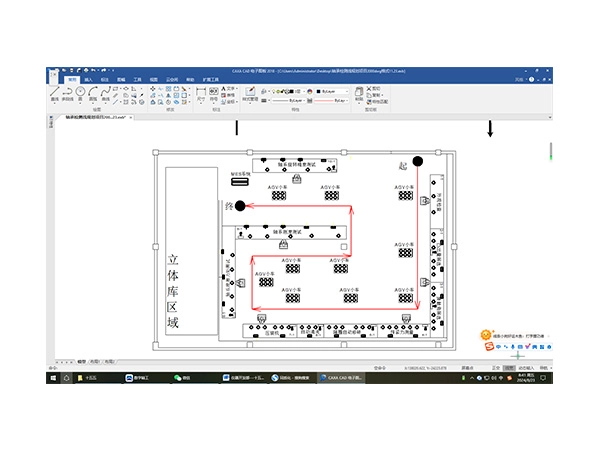

Automatic measurement, data transmission & storage, and measurement system integration technology

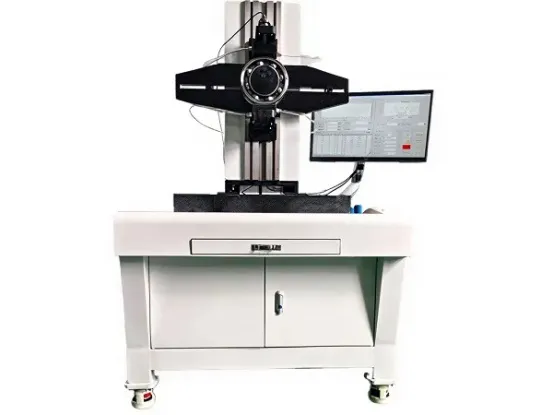

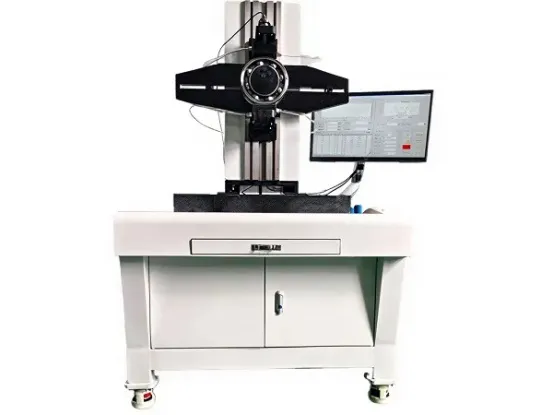

The high-speed roundness measuring instrument delivers precise, rapid, and reliable roundness measurements, ensuring superior accuracy for quality control in manufacturing and engineering applications.

Cylindricity measuring instrument is a precision device designed to accurately assess the roundness and straightness of cylindrical surfaces, ensuring high-quality manufacturing and tight tolerance control.

The surface profile measuring instrument is a precision device designed to accurately measure and analyze surface textures, roughness, and coating profiles for quality control in industrial and engineering applications.

The bearing axial clearance measuring instrument is a precision device designed to accurately measure the axial clearance of various types of bearings, ensuring optimal performance and reliability in mechanical systems.

Loaded Radial Clearance Measuring Instrument is a precision device designed to accurately measure the radial clearance of bearings under load, ensuring optimal performance and reliability in mechanical systems.

Bearings are manufactured to specific tolerance classes, such as ABEC (Annular Bearing Engineers Committee) for ball bearings and RBEC for roller bearings. A higher number (e.g., ABEC 7 or 9) indicates a higher precision bearing with tighter tolerances. Your measuring instrument must be at least as accurate as the bearing's specified tolerance class. Using a tool with lower accuracy will not allow you to properly verify the bearing's quality.

Determine exactly what you need to measure. Do you need to check the basic dimensions (ID, OD, width), or do you need to verify complex geometric properties like roundness, cylindricity, or surface finish? The tool must be capable of performing the required measurement.

For a high-volume manufacturing setting, automated, non-contact systems like laser micrometers are more efficient. For low-volume inspection or field maintenance, portable, manual tools like calipers and micrometers are more practical. The environment also matters; a clean, temperature-controlled laboratory is necessary for high-precision measurements, whereas a shop floor requires more robust, durable instruments.

The cost of bearing measuring instruments can vary widely, from a few dollars for a caliper to hundreds of thousands for an automated inspection system. Always consider the total cost of ownership, which includes not only the purchase price but also the cost and frequency of calibration. Precision instruments require regular, professional calibration to maintain their accuracy.

Wipe sensors and probes with lint-free cloth and isopropyl alcohol to prevent dust buildup.

Use certified reference standards to adjust instruments, documenting results for ISO audits.

Store in controlled conditions (20°C ±2°C, humidity below 60%) to avoid thermal drift.

If readings fluctuate, inspect for worn probes or software glitches; run diagnostic tests via ZYS app.

Replace contact probes every 6 months or after 10,000 cycles to maintain ±0.001mm accuracy.

Install firmware updates quarterly to enhance features and fix bugs.

Schedule annual servicing with ZYS technicians for comprehensive checks and recalibration.

For error codes, consult the manual or contact support; e.g., E101 indicates sensor misalignment.

Our sales team provides personalized consultations within 24 hours

All purchases include a 2-year warranty, free shipping, and access to our online training resources.

+86-15837918900

Download our comprehensive product catalog for full specifications, or schedule a live demo to see our instruments in action.