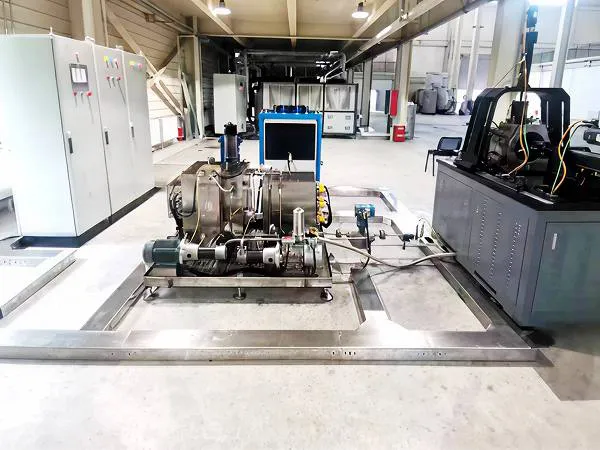

The testing machine development department has been deeply engaged in the wind power bearing testing business for many years and has formed a series of wind power bearing testing machine products, covering all bearing types in wind turbine generator sets. It has successively developed wind power yaw and pitch bearing testing machines, wind power main shaft bearing testing machines, wind power gearbox bearing testing machines, wind power generator bearing testing machines and other wind power series bearing testing machines.

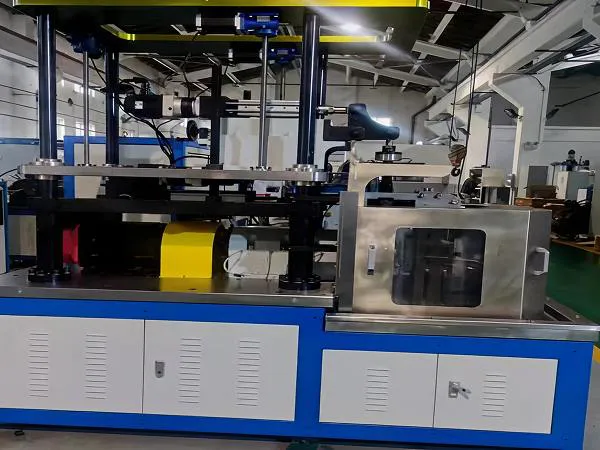

Rail transit bearing testing machines test bearings including rail transit traction motor bearings, full suspension bearings, axle box bearings, axle box bearings, and gear box bearings.

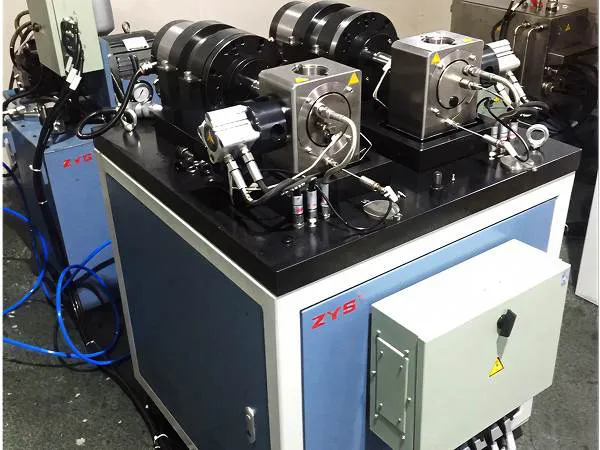

Bearing testing machines in the materials field are mainly aimed at verifying the performance of bearing raw materials related to bearings, and the related performance of lubricating oils and greases. The related equipment developed mainly includes material rolling contact fatigue testing machines, lubricating oil/grease bearing testing machines, lubricating oil high-temperature deposition testing machines, etc.

With the development of testing technology, the improvement of civilian bearing quality and the expansion of application fields in recent years, civilian bearing testing machines have continued to develop from the previous conventional fixed-load and fixed-speed life tests to the automation of test procedures and the diversification of test simulation environments, and from single testing machine models to group control, intelligence, and comprehensive management of test information.

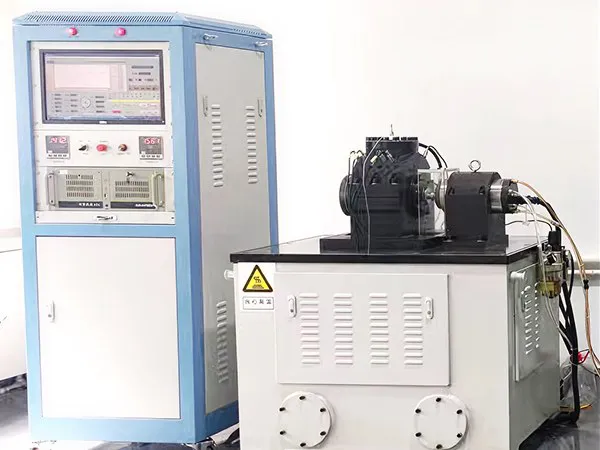

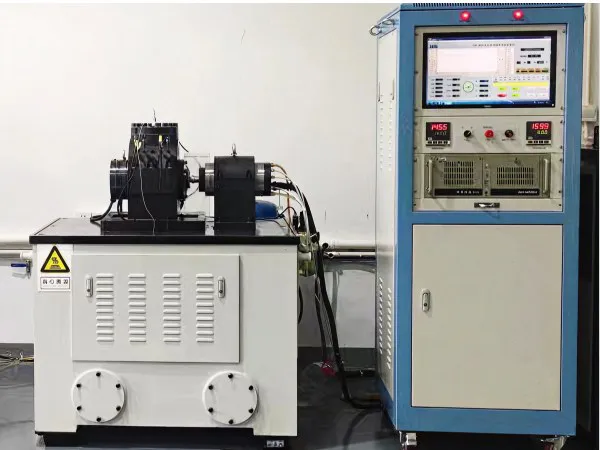

The bearing testing machine in the automotive field tests bearings covering automobile engine rocker arms, automobile wheel hub units, and new energy vehicle motor bearings.

Can measure inner diameters from Φ3 to Φ4000mm

Liquid hydrogen, liquid nitrogen, water media, environmental chambers, etc.

Low temperatures down to -196°C

Maximum speed of 120000rpm

Maximum Dn of 360x10^4 mm-r/min

Oil, air, heating rods, environmental chambers, etc.

High temperatures up to 500°C

Up to 2000kN

Hydraulic, electric, electromagnetic, etc.

Up to 1000kN

Hydraulic, electric, electromagnetic, etc.

Our machines are manufactured with premium materials and undergo rigorous testing to ensure durability and accuracy.

We incorporate the latest sensors, software, and automation features for precise data collection and analysis.

ZYS provides tailored testing machines to meet specific customer requirements and applications.

With our worldwide network, we offer comprehensive after-sales service, technical support and spare parts supply.

With decades of experience in bearing technology, ZYS understands the nuances of testing across various sectors.

Our machines deliver high ROI through reduced maintenance costs and improved product reliability.

ZYS products meet international standards like ISO and CE, ensuring compliance and safety.

Positive feedback from clients in automotive, aerospace, and other industries highlights our reliability.

Our sales team provides personalized consultations within 24 hours

All purchases include a 2-year warranty, free shipping, and access to our online training resources.

+86-15837918900

Download our comprehensive product catalog for full specifications, or schedule a live demo to see our instruments in action.