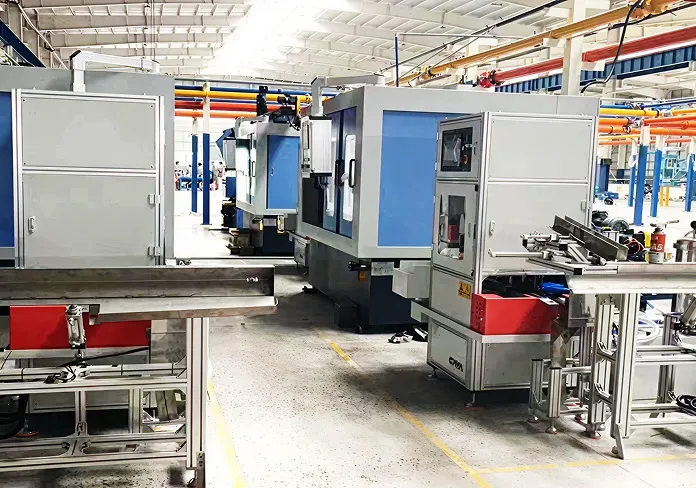

The cold rolling processing line is mainly composed of a cold rolling machine, an automatic cleaning and measuring machine, a material turning machine, an elevator, etc. The cold rolling processing line improves the automation level of the cold rolling machine, realizes automatic loading of cold rolled blanks, automatic cleaning and automatic measurement of cold rolled finished products, and can effectively improve the cold rolling processing efficiency and processing quality.

It is used in bearings, automobiles, motorcycles, oil pump nozzles, hydraulic parts and other industries, especially suitable for super finishing of cylindrical and tapered rollers.

It can mass-produce special bearing processing equipment such as CNC bearing ring turning equipment and automatic lines, fully automatic grinders, super finishing machines, bearing ring precision cold rolling machines, semi-automatic multi-purpose grinders for micro ball bearing rings, and ball bearing super-automatic grinding production lines.

Bearing manufacturing equipment is essential for producing various types of high-precision bearings, including ball bearings, roller bearings, and needle bearings.

01These machines automate core processes such as grinding, assembly, and inspection, ensuring exceptional precision and production efficiency.

02ZYS focuses on designing and manufacturing cutting-edge equipment that meets international advanced standards, with our products widely used in the global automotive, aerospace, and machinery manufacturing industries.

03With decades of technological accumulation, we provide reliable solutions that effectively reduce production costs and enhance output quality. Choosing our technology means empowering long-term production benefits and innovation.

04Our machines achieve micron-level accuracy for consistent quality.

Built with robust materials to withstand harsh industrial environments.

Designed to reduce power consumption and lower operational costs.

Fully automated systems minimize manual labor and increase throughput.

Options to tailor machines to specific production requirements.

User-friendly design with accessible components for quick servicing.

Integrated safety protocols to protect operators and equipment.

Long lifespan and low maintenance reduce total cost of ownership.

Over 30 years of experience in bearing machinery manufacturing

Continuous R&D to incorporate the latest technologies.

Machines exported to over 50 countries worldwide.

24/7 technical assistance and training programs.

Comprehensive warranty coverage for all products.

Ability to design machines based on client specifications.

ISO 9001 certified ensuring high standards.

Competitive pricing with long-term value.